The Project

3 Replacement Control systems for offshore based SGT-200 Gas Turbines

In 2017 Proeon were approached by a major energy producer to look at the options available to them to provide long term support for 3 industrial gas turbine control systems located in the inhospitable North Sea offshore.

The installation is one of the client’s headline facilities, and the obsolescence of control systems had already been identified as a risk for the long-term safe operation of the asset.

Proeon, has a proven track record of providing non-OEM based Gas Turbine support and control systems retrofits and were a strong fit for providing a complete integration service bringing together legacy turbines with new control systems based on our own bespoke IP, to provide a single procurement interface and deliver a complete solution.

The Challenge

Proeon supported the client through site visits, offshore surveys, and multinational meetings to develop a workable solution in the time frame and budget constraints, and by late 2019 with all the operational considerations for the client, the 18-month project started.

The project scope included the replacement turbine control systems for the three SGT-200 gas turbines complete with a new fuel control train and compressor load control.

The existing turbine control systems were the original Rustronic control systems, and the detailed survey identified a solution to supply pre-assembled panels to be installed within the existing steelwork. The design sought to replace the existing Rustronic Mk II, HMI, BN3300 VMS and CCC 3+ hardware within the turbine control module enclosure and use the existing field cabling and wiring. This represented a significant saving in both resources, materials and time.

Proeon can provide gas turbine control solutions based on both Siemens and Rockwell platforms and have a range of standard control and safety upgrade solutions for most aero or Industrial GT engine types for both mechanical and electrical drive applications.

The selected control solution provided was based on a Rockwell ControlLogix PLC system complete with a replacement HMI for integration into the existing platform DSCS systems architecture. The turbine control system also included for the upgrade of the vibration monitoring system to utilise the Bently Nevada BN3500 together with an upgrade of the CCC load and anti-surge control system to CCC 3++. A separate HIMA safety controller provided independent overspeed and machinery protection logic.

Proeon worked closely with the client’s site team to accommodate a challenging installation programme which resulted in the client opting to have the control packages pre-installed in new panels to reduce the offshore workload, simplifying storage and increasing the available installation windows.

The entire retrofit control systems were manufactured at our facilities in Norfolk.

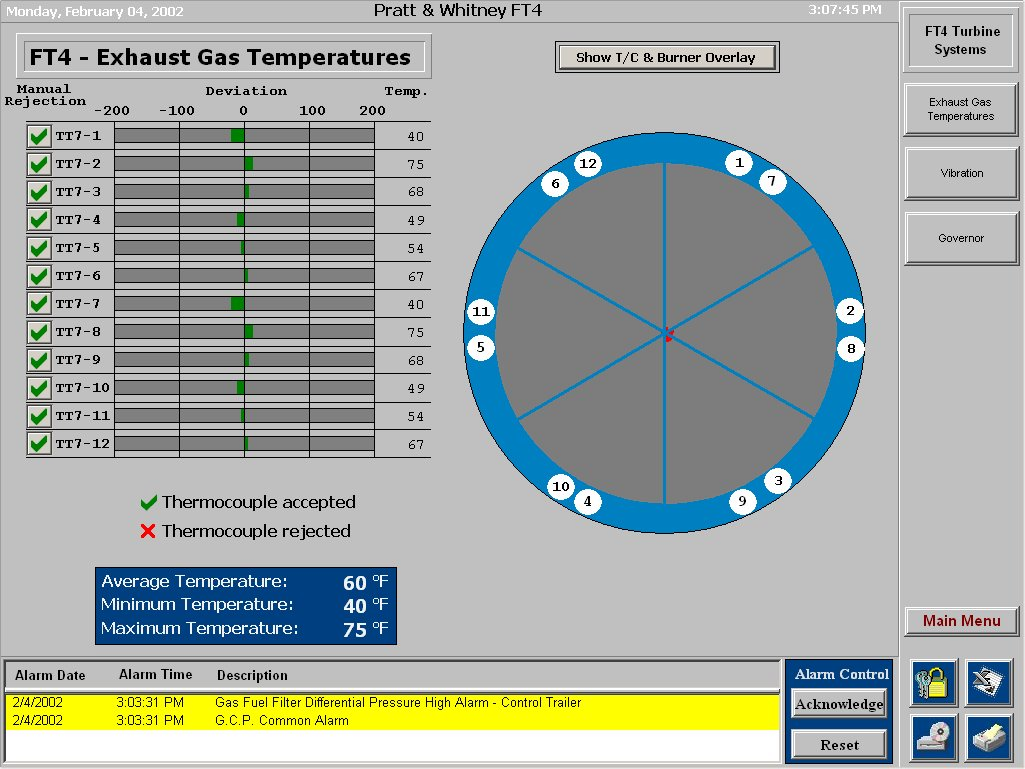

The local HMI workstation provided control and diagnostics of the gas turbine with application software based on the graphics from the original control system. New screens and functionality were added to support the new functions, diagnostics and live monitoring of the BN 3500.

The HMI displayed the following typical information.

Turbine overview

Turbine control

Fuel system overview

Main Lube Oil system

GG Lube Oil System

EGT thermocouples

Sequence flow charts

Cooling Systems

Governor overview

Vibration Monitoring

MCC

Surge Control

Alarms

Real time and historical trending

In Conclusion

The Proeon Proeon non-OEM Turbine Control package is based on our range of field proven control algorithms running on standard PLC platforms as has been honed with years of experience in retrofitting a range of engine types. As with many projects Proeon supplied the client the following services:

Complete integrated gas turbine control system including governor, EGT and sequencer with independent safety controller and vibration monitoring system

Compressor load control system

Fuel system upgrade kit for the gas turbine including intelligent gas fuel metering valve, shut-off valves and spool pieces

Desktop remote access PC to integrate with and monitor all 3 gas turbines

Engineering laptop with pre-installed engineering and support software

Supply of comprehensive project documentation pack including quality plan, project plan, electrical schematics, FDS, BOM, GA, O&M, MRB etc.

Complete assembly & testing of the integrated system at our premises in Norwich, UK

Off-shore installation and commissioning services

Spare parts for commissioning and 2-year operation

The client has now formed a larger formal arrangement with Proeon for further projects on their expanding ageing assets both onshore and offshore.

For further information on GT turbine upgrades, experience, previous projects and how we can help you, please do not hesitate to contact us directly

Contact us for more information:

Proeon Systems Limited Email: proeon@proeon.co.uk Tel: 01953 859 110 www.proeon.co.uk